Air Springs “Problem – Cause – Solution”

Problem and Cause

Solution

|

Deformed Air Springs · improper storage · improper transport · improper handling |

|

|

· storage according to ISO 5285 no daylight, dry, at normal room temperature · avoid improper transport · avoid improper handling |

|

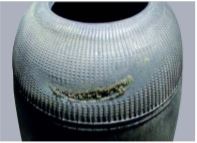

Damage of the conical beads and cuts · improperly mounted bead plate · pinching of the bellows with metal parts |

|

|

· keep conical beads clean and corrosion free · avoid driving without pressure in the air suspension |

|

Bellows rubs off at shoulder · bead plate diameter incorrect · bellows too long for application |

|

|

· make sure to use original parts · avoid wrong cross references |

|

Broken off thread bolts · excessive torque · use of oils or lubricants |

|

|

· don’t exceed recommended torque according to your maintenance manual · avoid usage of oils or lubricants |

|

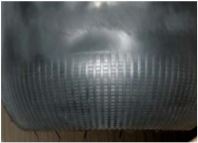

Overextension · spring travel not restricted · incorrectly adjusted level control · air spring not suitable for application |

|

|

· check the shock absorbers · check and adjust level control valve · double check if the air spring fits the OE part number |

|

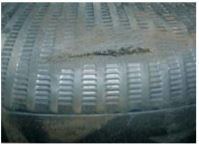

Abrasion · Bellows contact with chassis parts · Bellows contact with foreign bodies |

|

|

· double check if the air spring fits the OE part number · check regularly and remove foreign objects stuck between bellows and piston |

|

Chemical contamination · usage of oils or lubricants |

|

|

· avoid usage of lubricants or cleaners which contain mineral oils · check air springs on a regular basis |

|

Air Spring bursting, broken piston · overload · exceeding the maximum allowable pressure |

|

|

· never exceed the maximal allowed weight of the vehicle |